Operating platform in aluminum

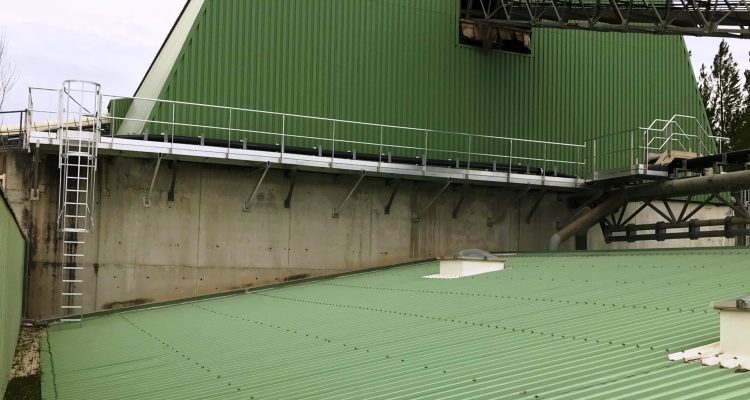

Our client asked us to size an access bridge, as well as an aluminum operating platform for the maintenance of the pipes in the factory in which these structures are located.

Our client asked us to size an access bridge, as well as an aluminum operating platform for the maintenance of the pipes in the factory in which these structures are located.

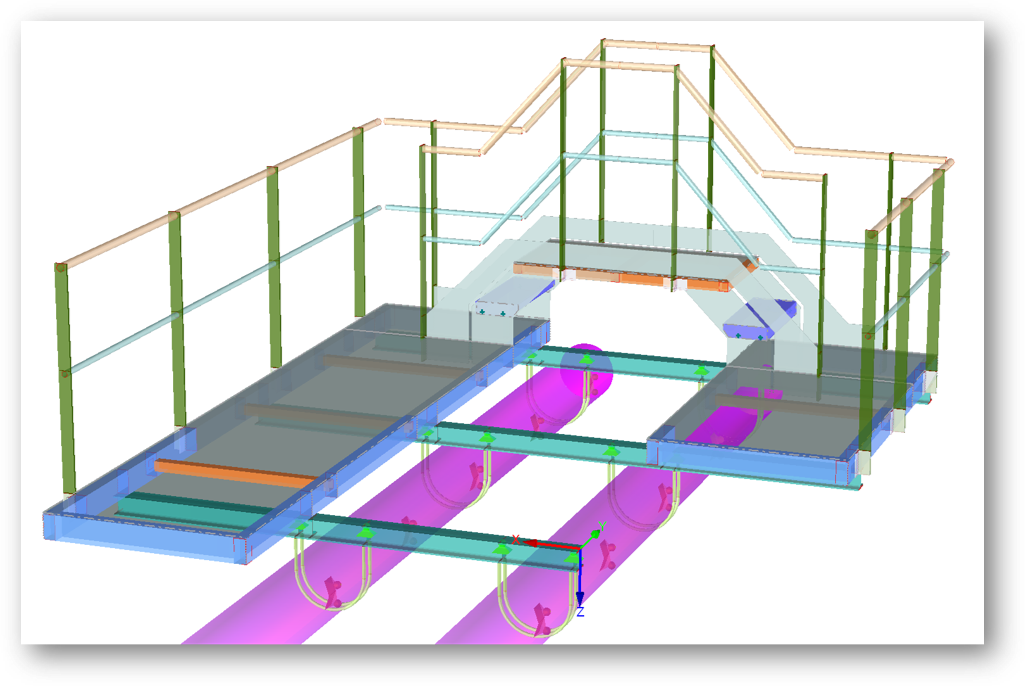

The access walkway has the particularity of being self-supporting and fixed at right angles to a vertical concrete wall. The operating platform is placed on the pipes, using crosspieces and clamps.

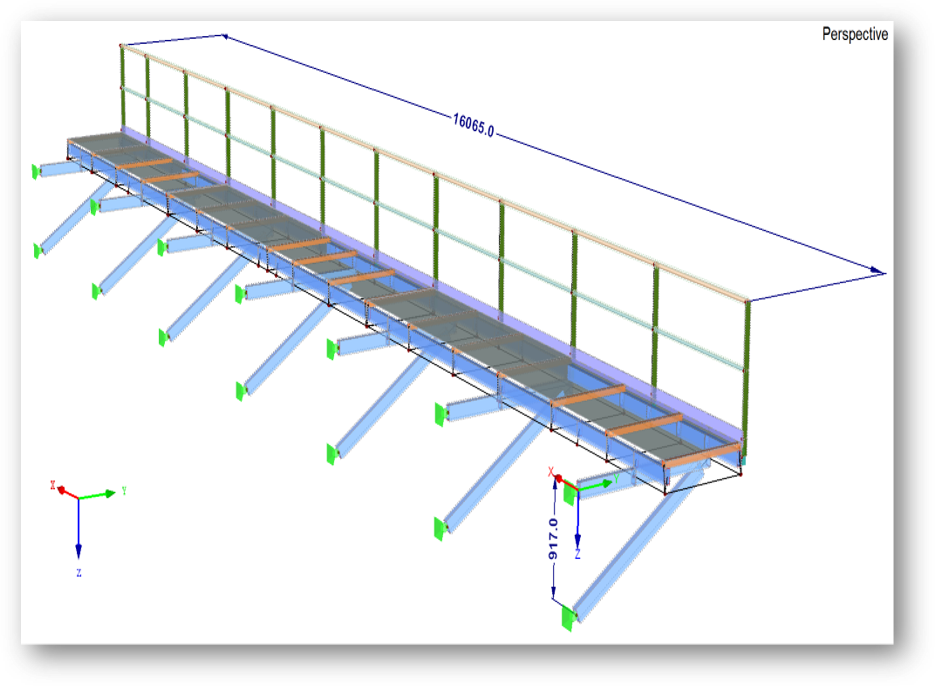

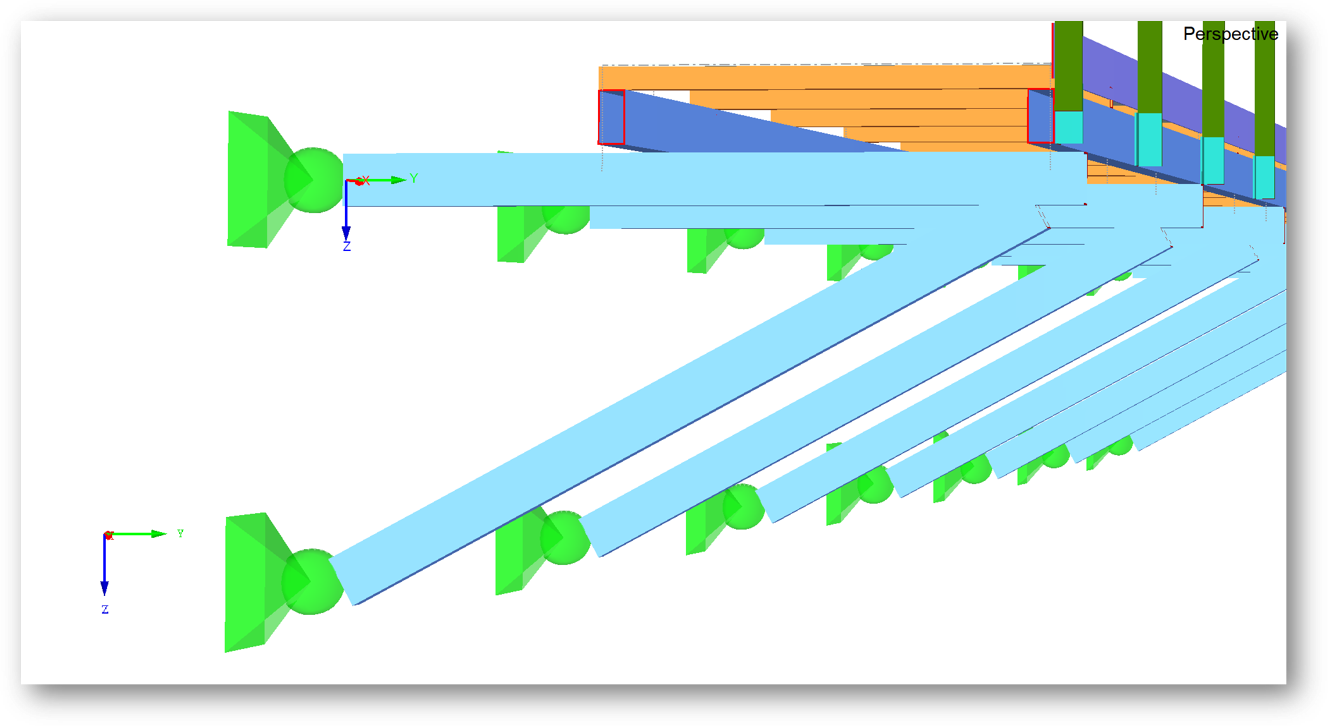

We started our study on the basis of the plans he made, in DWG format in order to transform them into a calculation model (in nodes, lines, bars, sections and surfaces). We define the bars, beams, sections, pilasters and rails of railings as being 1D elements. Plates, reinforcements, skirting boards are defined as 2D surface elements to which a thickness has been assigned.

We started our study on the basis of the plans he made, in DWG format in order to transform them into a calculation model (in nodes, lines, bars, sections and surfaces). We define the bars, beams, sections, pilasters and rails of railings as being 1D elements. Plates, reinforcements, skirting boards are defined as 2D surface elements to which a thickness has been assigned.

The walkway is fixed to the vertical wall of the building through plates, which are the subject of a separate study. Indeed, we first study the reactions to the supports (here, simple nodal supports with 3 degrees of freedom in rotation X, Y and Z).

The walkway is fixed to the vertical wall of the building through plates, which are the subject of a separate study. Indeed, we first study the reactions to the supports (here, simple nodal supports with 3 degrees of freedom in rotation X, Y and Z).

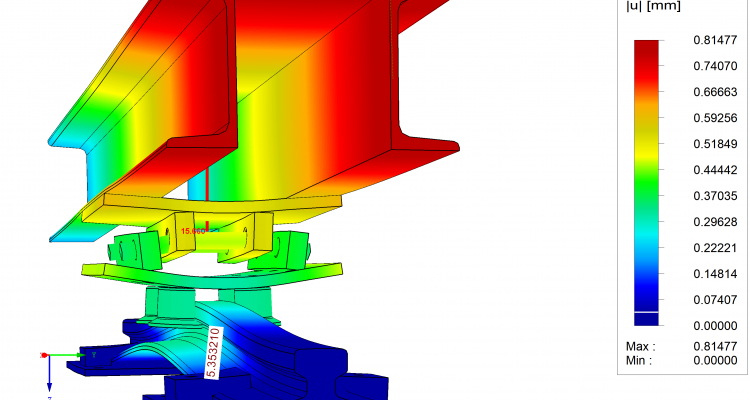

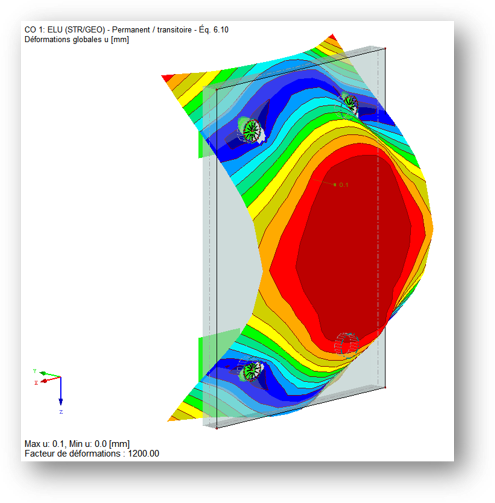

Then, these reactions are transmitted in the separate model of the plate, where we will study in detail the reactions to the anchor studs (main shear and traction due to the tearing effect).

After an adaptive mesh, tighter on the bars and bracons, we check the sections initially drawn by our client according to Eurocodes 3 (steel) and 9 (aluminum). We carry out a double verification by the equivalent constraints admissible according to the Von Mises criterion.

In the event that the verifications cannot be accepted, we offer our client, with our know-how, solutions to improve the resistance: reinforcements, increase in sections or thicknesses up to ” to obtain the best optimal holding / economy ratio.

Conversely, if the checks are satisfactory in the extreme, we offer him an optimization of the sections in order to gain weight and economy.

Our client therefore obtains a structure OPTIMISÉE with the certainty of its resistance over time.

On this model, optimized and validated with it, we are editing a clear calculation note divided into chapters for better reading and efficient indexing.

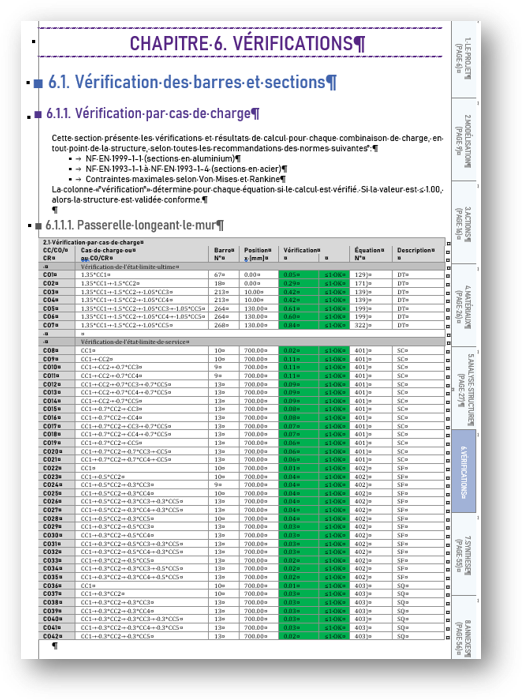

Chapter 6 concerns all the checks carried out according to the equations of the Eurocodes in question:

- EN 1993-1-1 (for steel parts)

- EN 1999-1-1 (for aluminum parts)

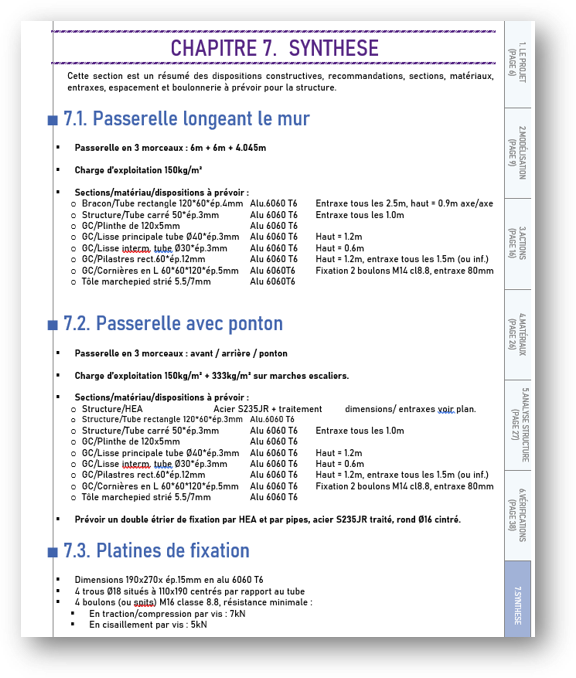

Our calculation note always ends with a chapterSUMMARY, one or two pages maximum, in which we summarize all the main information of the structure: materials, loads, sections, fixing parts to provide. So our client knows at a glance the information he needs to test his structure or to simply start manufacturing calmly.

Our calculation note always ends with a chapterSUMMARY, one or two pages maximum, in which we summarize all the main information of the structure: materials, loads, sections, fixing parts to provide. So our client knows at a glance the information he needs to test his structure or to simply start manufacturing calmly.

Thank you to our client for having trusted us for the verification and optimization of its structure.

Do you have a design project for a mixed steel / aluminum structure?

Do you want a design office calculating partner that offers you optimization (cost, weight gain or improved hold)?

You want responsiveness, speed of execution?

We are your contact.

Do not hesitate to contact us !