Verification of a mechanical translation system

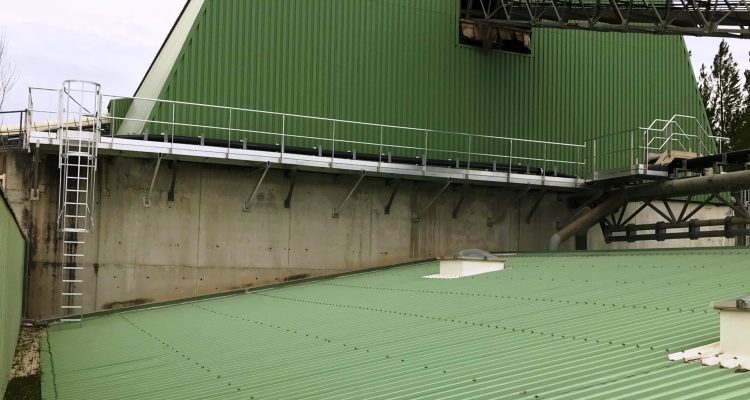

Our client contacted us in order to verify the resistance to a tensile stress of a mechanical assembly of double translation on rail of a hydroelectric dam.

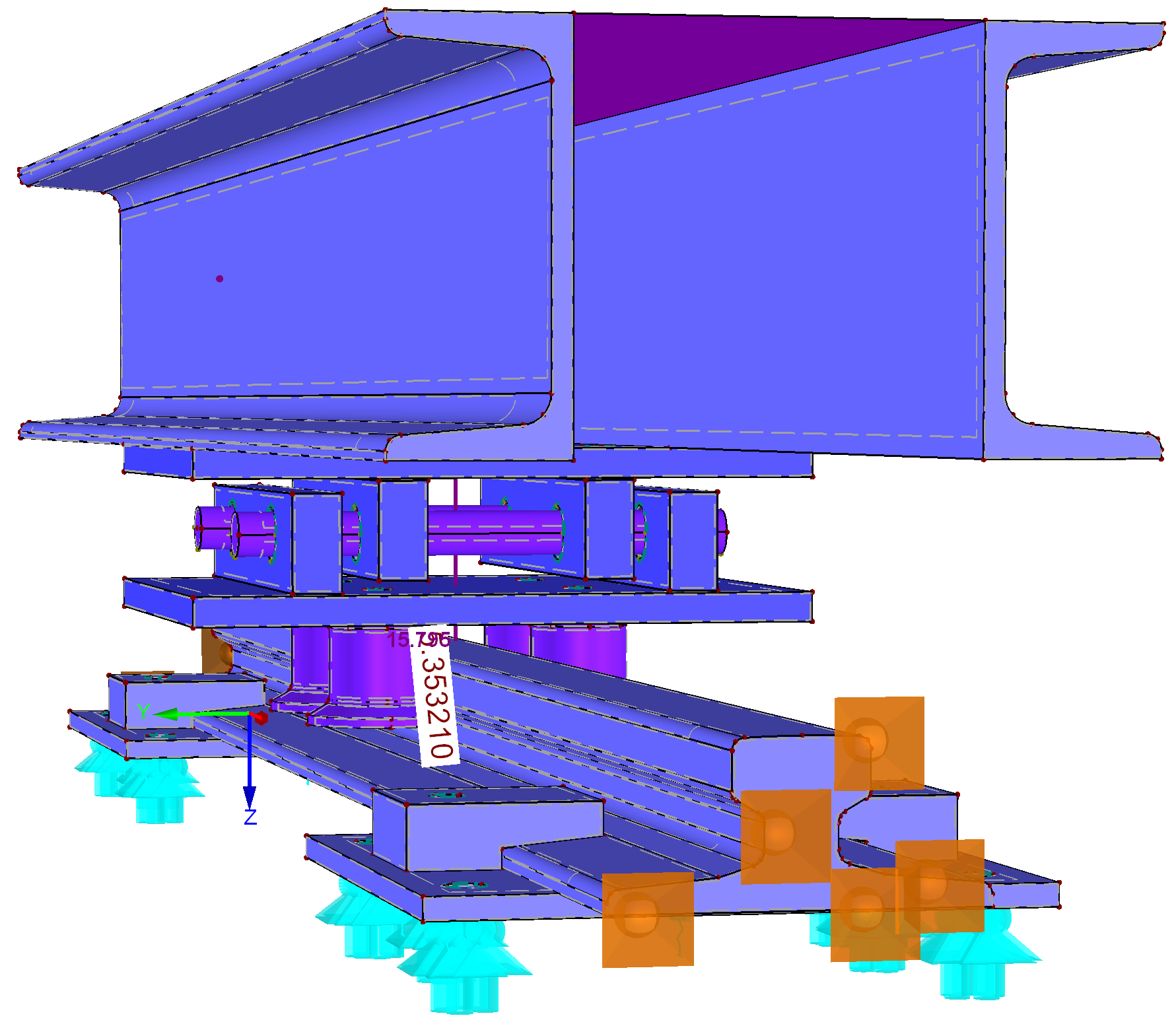

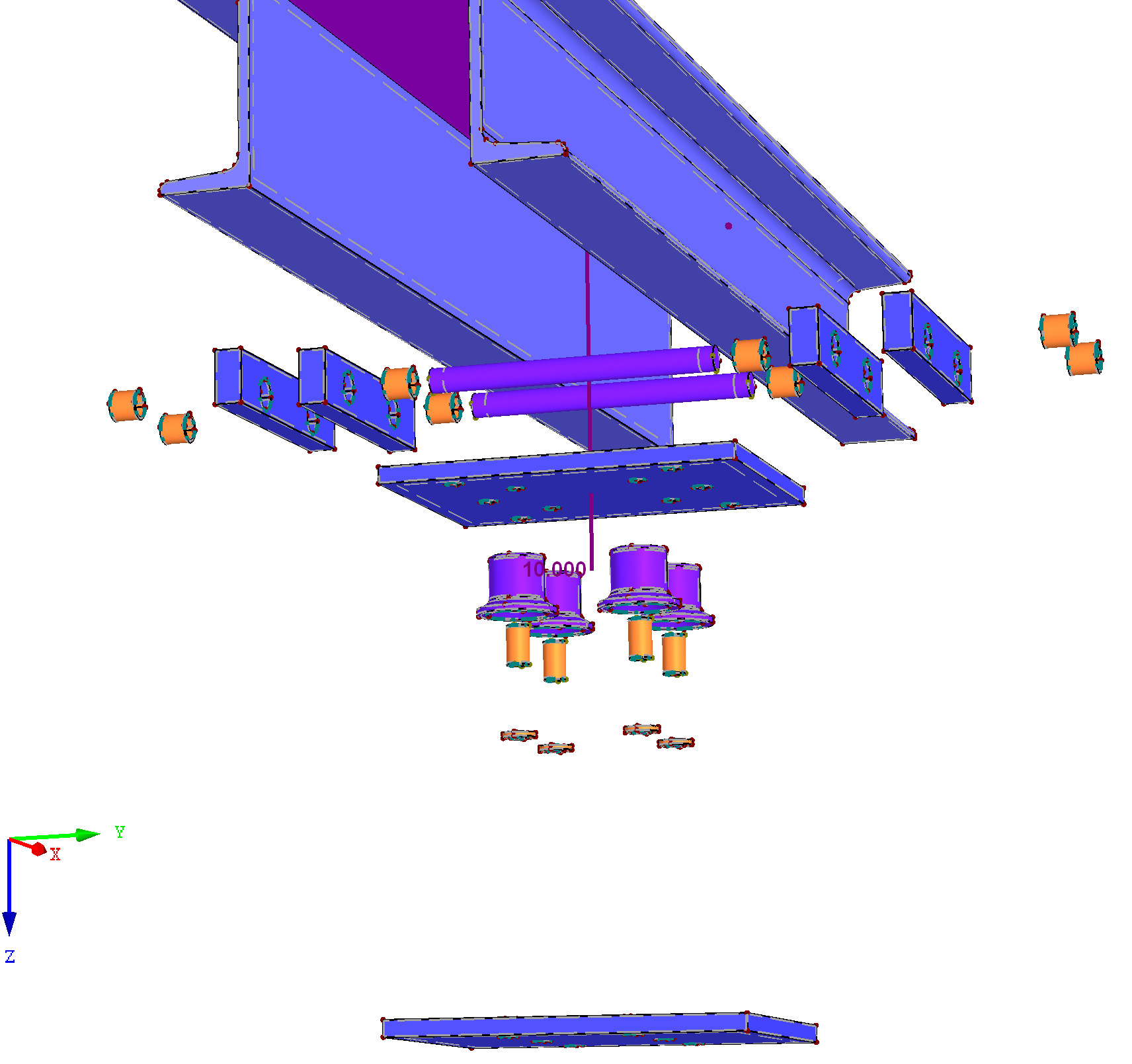

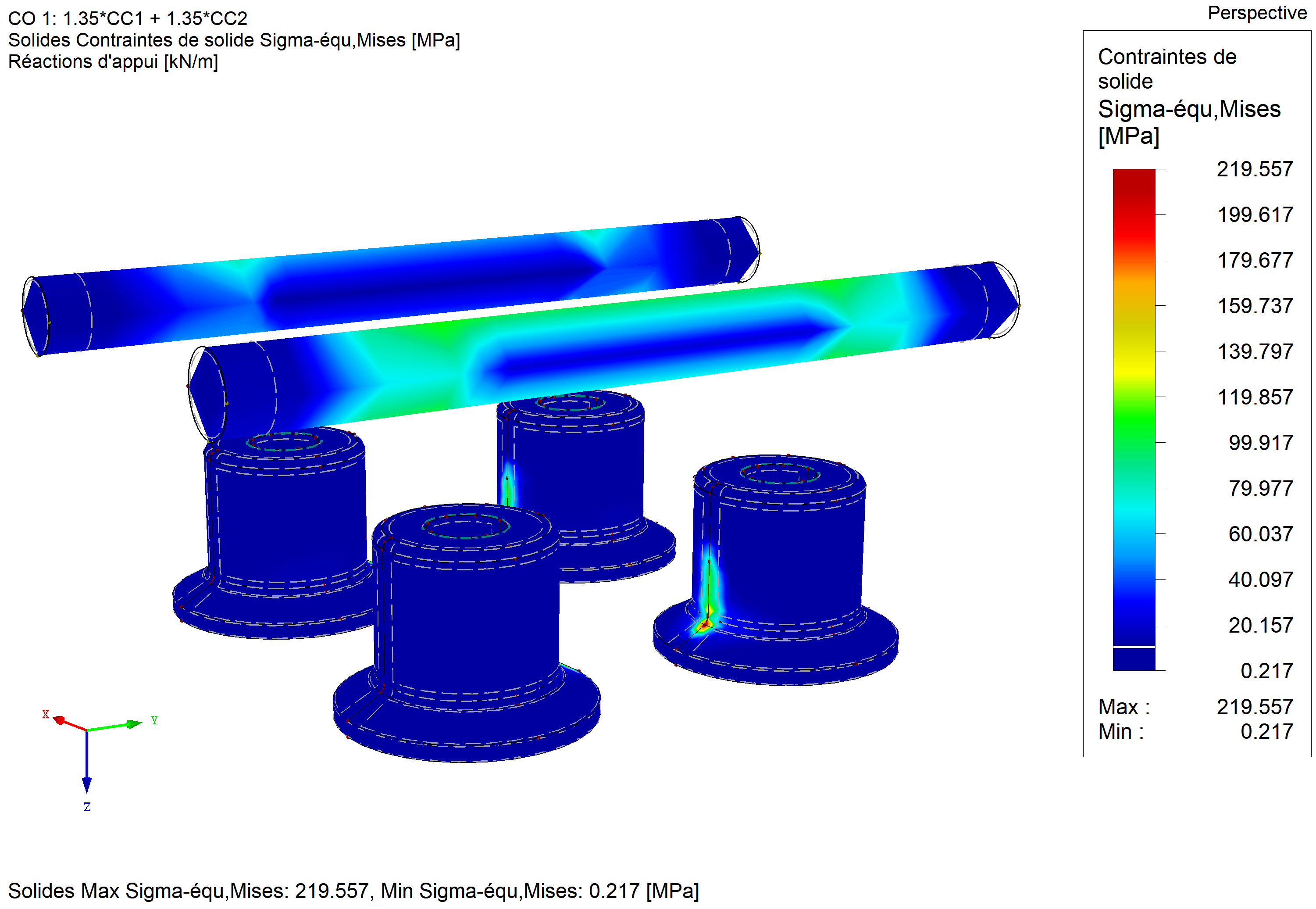

The calculation modeling is composed of different solid bodies with different materials (steel S235, S275, bronze, steel 42CD4). The rail is blocked on the ground with toads fixed on base plates. The assembly can translate thanks to 4 rollers, themselves fixed on a sub-assembly of slides, which ensure the translation both on X and on Y. The whole of the supported structure is represented by the double UPNs.

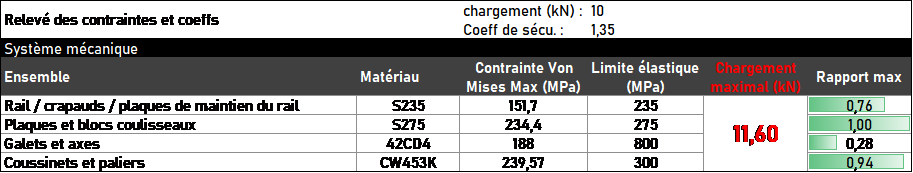

The tensile force not being defined, we verify this model under a calculation in iterative mode, until reaching the limit of stability and the elastic limit of each material, by taking into account a safety coefficient specific to Eurocodes .

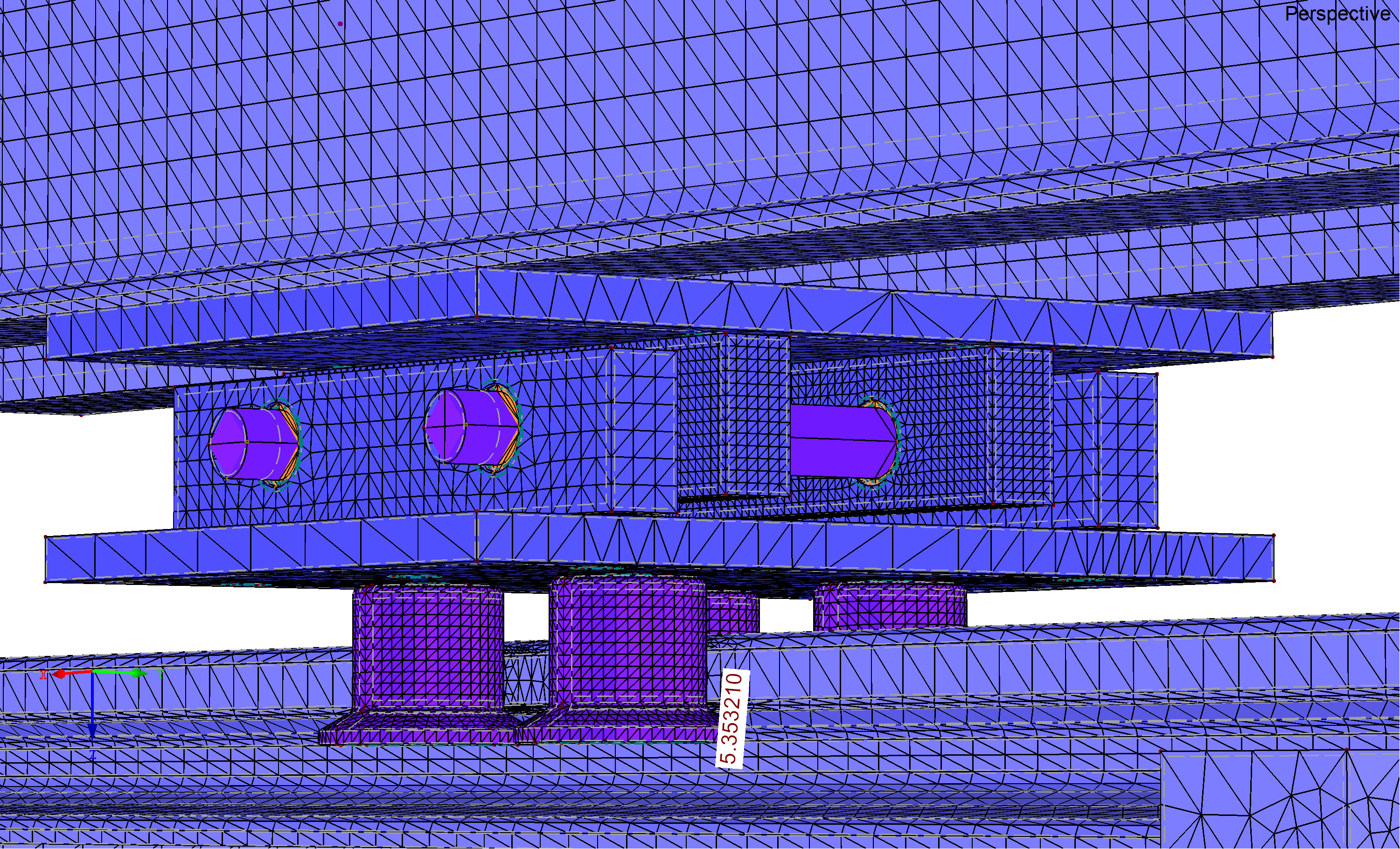

We take the choice to calculate each part in solid mode (3D finite elements) in order to check at each point of matter if the contact constraints and internal deformations are not detrimental to the behavior of the part in question. Below the representation of the finite elements, for a desired mesh relatively fine.

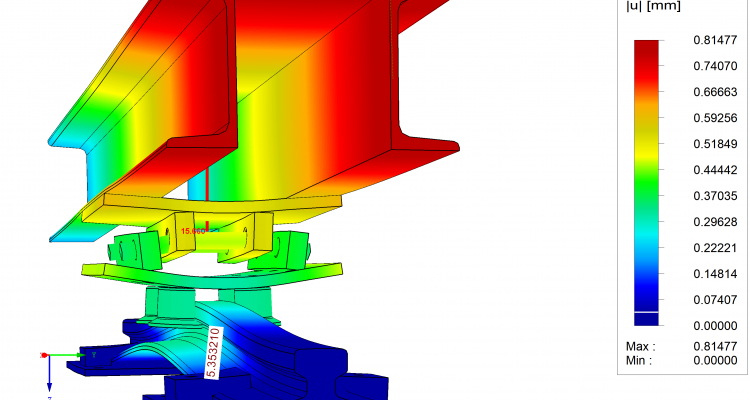

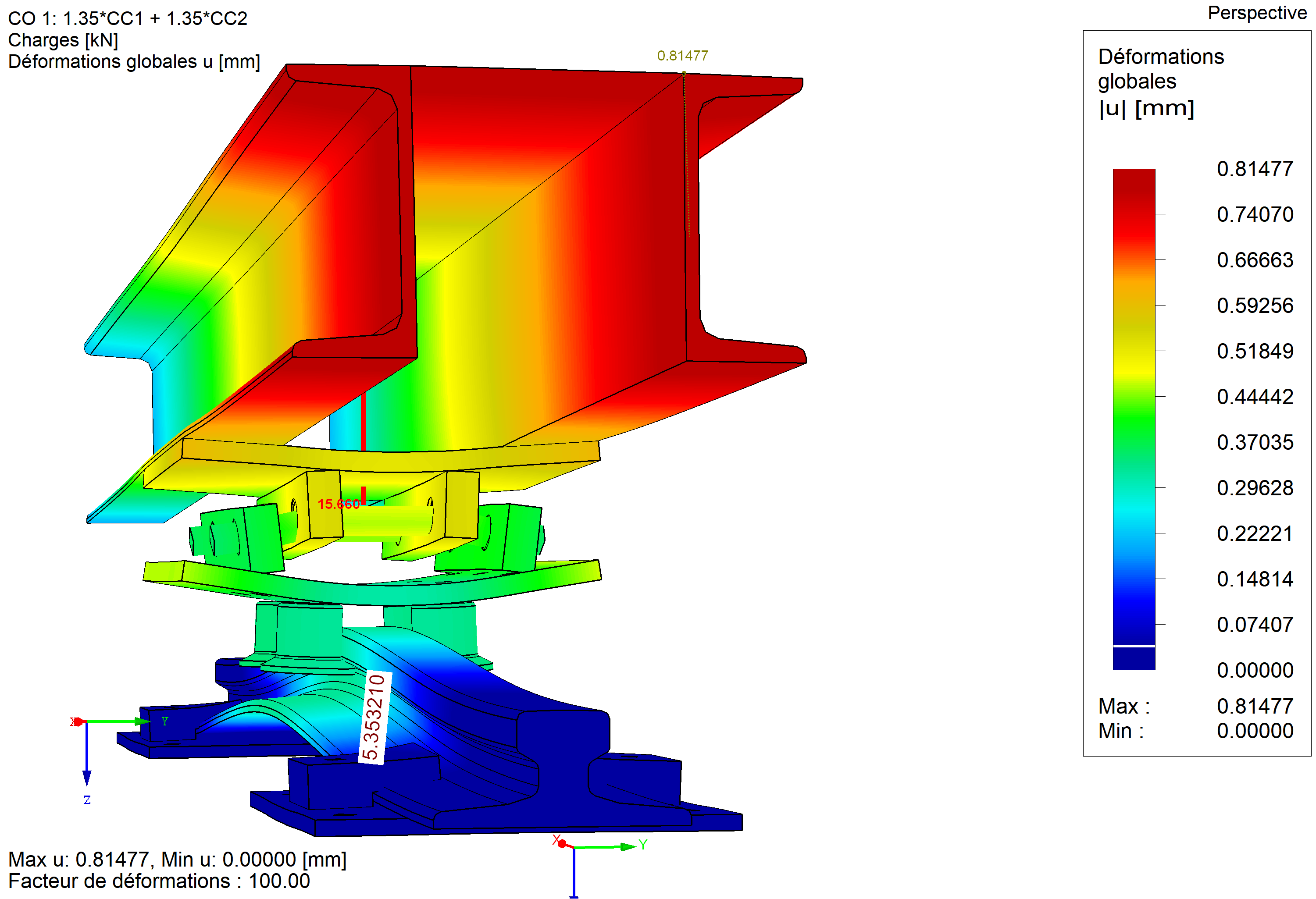

After calculation, we check in a first if the deformation obtained seems to correspond to reality, which is the case here.

After calculation, we check in a first if the deformation obtained seems to correspond to reality, which is the case here.

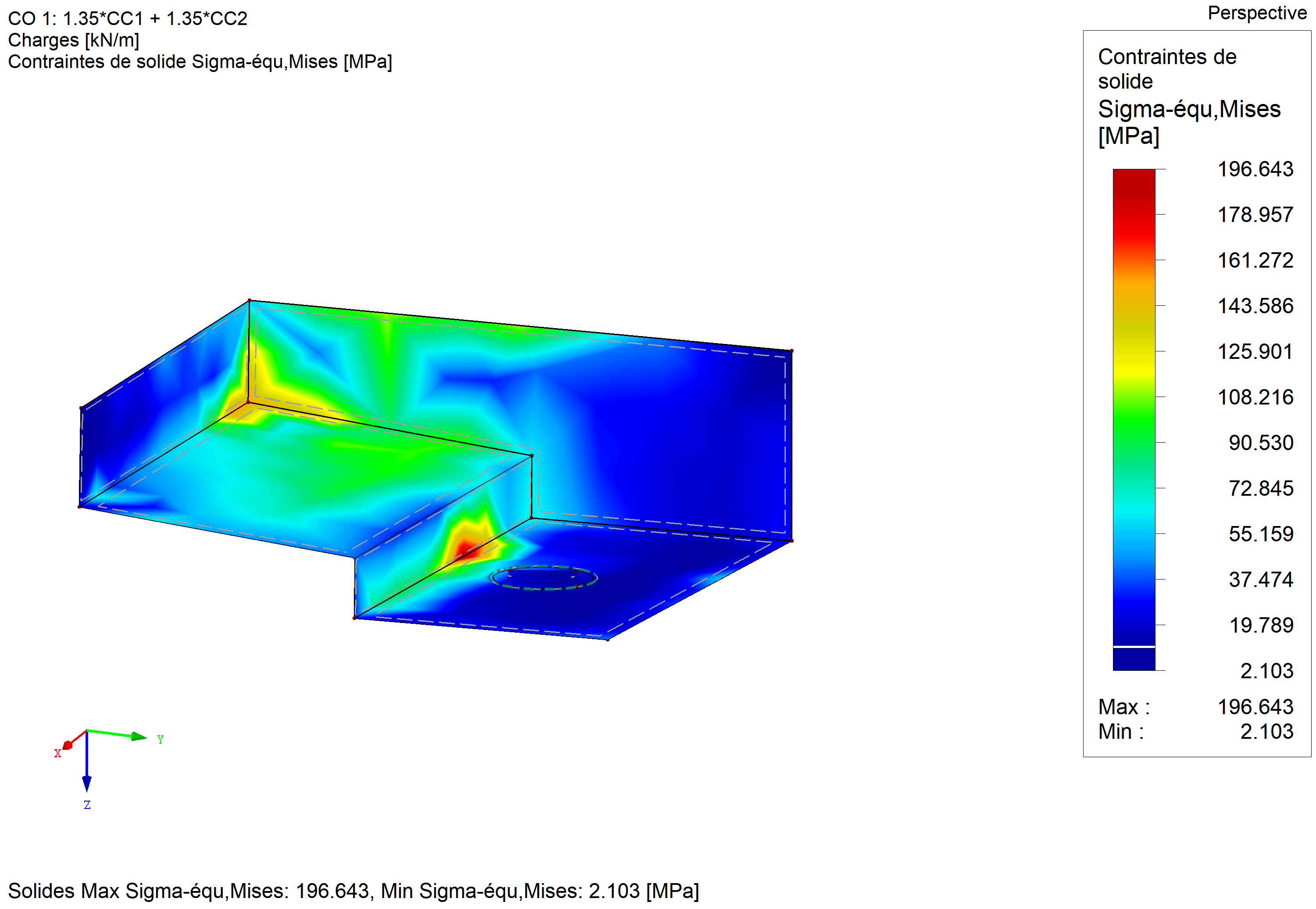

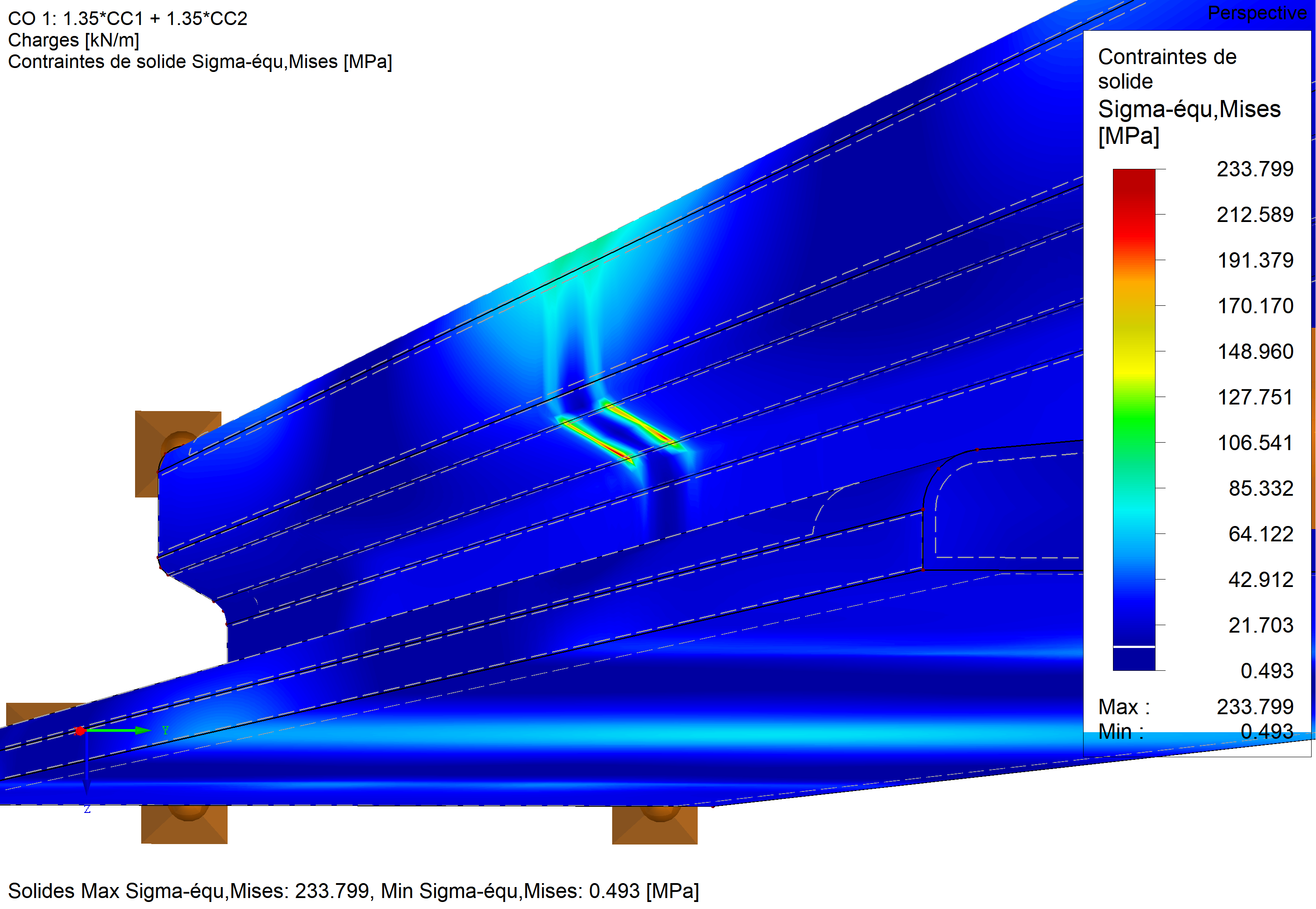

Then, each sub-assembly of the same material is isolated in order to check the maximum deformation constraints according to the Von Mises criterion, opposite and below a toad, the axes and rollers, the contact constraints of the rollers on the rail.

Then, each sub-assembly of the same material is isolated in order to check the maximum deformation constraints according to the Von Mises criterion, opposite and below a toad, the axes and rollers, the contact constraints of the rollers on the rail.

The force being unknown, our calculations are done in iterative mode until reaching the limit of stability or the reaching of the elastic limit of materials, and to deduce from it the maximum admissible force in the system. We therefore have a maximum admissible load in this system of 1.16 tonnes.

A calculation note is published which retraces all the results, input data, and checks carried out.

Thank you to our client for trusting us.

Contact the AGICEA design office if you have mechanical systems to check and / or size

We will be happy to help you with your project.